CaseStudy: Pawi Packaging

When Pawi Packaging GmbH opened its state-of-the-art folding carton plant in Singen, Germany, the company needed pallet solutions that met the stringent hygienic standards of the food packaging industry while supporting high-volume, lean manufacturing. After extensive testing, Pawi selected Jeco Plastic Products—a U.S. manufacturer known for durable, precision-engineered plastic pallets trusted by printers worldwide.

Challenge: Meeting Stringent Hygiene and Efficiency Standards

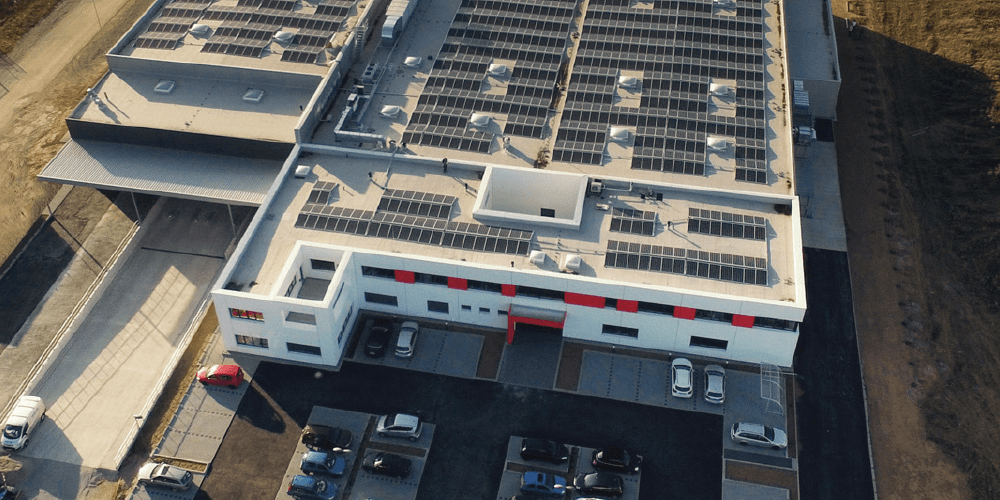

The new 172,250-square-foot facility, completed in under a year, was designed around modern lean production principles. Half the building houses a high-bay racking system for 16,000 pallets, and the plant employs roughly 60 workers, with plans to double output by 2020.

Pawi’s Managing Director Ralf Kautzmann explained:

“Our primary focus is to produce folding cartons in a lean and flexible manner to serve our food customers, who require very stringent hygienic standards and certification.”

Traditional wooden pallets presented multiple challenges:

- They can harbor insects and contaminants, compromising cleanroom-level operations.

- Splinters and rough surfaces pose safety risks for employees.

- Their weight and limited lifespan reduce efficiency and add long-term costs.

Contact Us Today>

Solution: Switching to Jeco Plastic Pallets

After rigorous testing, Pawi Packaging chose Jeco plastic pallets, which are:

- Virtually indestructible, even under heavy paper loads.

- Lightweight and easy to handle for employees.

- Accessible from all sides by hand trucks and forklifts.

- Made from 100% virgin LLDPE resin, ensuring strength, cleanliness, and durability.

- Approved by Heidelberg for use in its Logistics systems.

Kautzmann added:

“These pallets meet the high standards of the food industry for folding carton package production systems. Wooden pallets often break under heavy weight, but Jeco’s do not require repair or replacement.”

Results: Leaner, Safer, and More Hygienic Production

With Jeco pallets integrated throughout the plant—from the Heidelberg XL 106 press to Bobst die cutters—Pawi achieved:

- A cleaner, safer production environment that meets food industry hygiene standards.

- Reduced downtime and pallet maintenance thanks to Jeco’s unmatched durability.

- Operational efficiency gains, with lighter handling and consistent pallet performance.

Operator Guiseppe d’Apolito noted the lightweight and hygienic design made daily operations noticeably smoother.