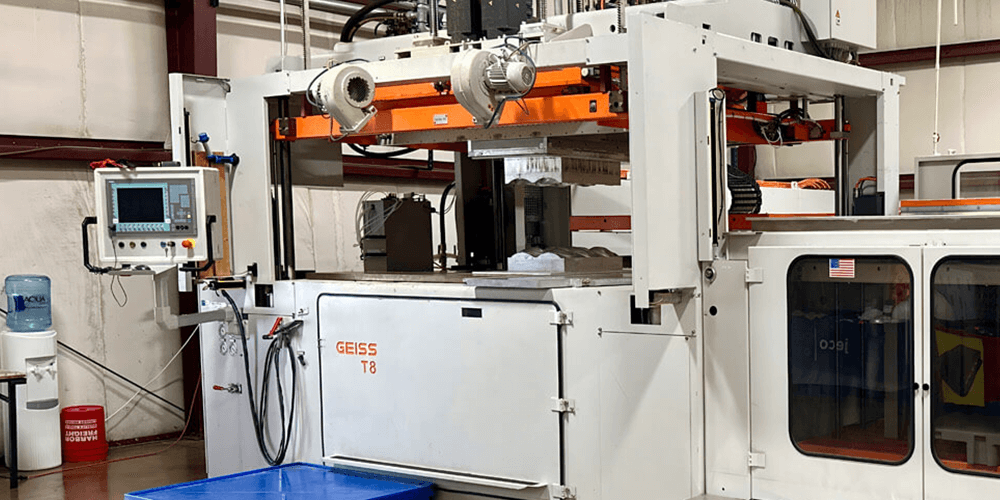

Advanced Thermoforming Solutions: Custom Composites, Twin-Sheet Forming, and High-Performance Plastics at Jeco

What Sets Jeco’s Thermoforming Apart

Thermoforming is one of the most flexible processes in modern manufacturing, heating a plastic sheet and shaping it into strong, dependable components used across industries from packaging to aerospace.

At Jeco Plastic Products, thermoforming goes far beyond conventional forming. It’s an engineered, highly technical process combining advanced materials, custom laminates, and precision forming to solve complex challenges in aerospace, defense, automotive, industrial, and specialty applications.

Jeco designs custom components that blend thermoplastics with complementary materials, allowing manufacturers to achieve targeted strength, weight, thermal, and durability characteristics not available through standard thermoforming. Their engineers regularly replace heavier metal parts with lightweight thermoplastic composites that maintain structural integrity while reducing cost and weight.

Advanced Heating Technology for Precision Parts

To achieve tight tolerances, consistent quality, and high-performance finishes, Jeco uses a suite of advanced heating systems:

- Short-wave halogen heating that warms material from the inside out for reduced cycle times and lower energy use.

- Dual heating tables that heat materials from both sides for even forming.

- Individually adjustable heater patterns that allow precise control and “heat tuning” for each part.

- Electric and water tool heating/cooling to tightly control mold temperatures—critical for composite materials and high-precision applications.

This level of heating control supports clean surfaces, crisp details, and reliable repeatability.

High-Performance Forming Capabilities

Jeco’s forming technologies allow the production of complex, high-strength, multi-layer, or hollow structures that traditional thermoformers can’t match.

Capabilities include:

- Vacuum forming for fast production and low tooling costs

- Pressure forming using male and female molds for sharper definition and highly detailed surfaces—supported by up to 20 tons of pressure

- Twin-sheet forming to produce hollow structures, lightweight parts, or multi-layer assemblies

- Specialized carbon-fiber clamping systems, with 14 independently moving clamps, that eliminate wrinkling in rigid or non-stretch composite materials

This engineering depth makes Jeco uniquely suited for advanced composites and structural components.

Twin-Sheet, Pressure Forming, and Composite Laminates

Jeco is one of the few U.S. thermoformers capable of combining multiple materials into engineered laminates during the forming process. This includes:

- Carbon fiber layers embedded between polyethylene or polypropylene sheets

- Multi-layer laminate structures with continuous glass or carbon fibers

- Twin-sheet TPU elastomers

- Complex thermoplastic armor backup structures

These laminates offer unique properties—strength, stiffness, thermal resistance, EM transparency, or impact absorption—that aren’t commercially available in off-the-shelf sheet materials.

Large-Format Thermoforming With Rapid Changeovers

Jeco supports both small and large-format production with:

- Maximum sheet sizes up to 1680mm x 1450mm (66” x 57”)

- Automatic sheet loading for continuous operation

- Quick-change tooling is ideal for short runs or prototype-to-production workflows

- Particle-controlled forming environments for Class-A finishes and optical clarity

This flexibility allows Jeco to deliver everything from one-off development parts to high-volume production runs efficiently.

Specialized Materials for Extreme Performance

Jeco works with some of the most advanced materials available in thermoforming, including:

- PPS with continuous carbon fiber

- PEKK, including multi-layer PEKK/carbon fiber laminates

- PA6 with continuous glass fiber

- Curv® polypropylene composites

- Evonik structural foams

- Twin-sheet TPU elastomers

- Acrylic and polycarbonate up to 50mm thick for optical or impact applications

These materials allow Jeco to manufacture lightweight, high-strength, thermally stable, chemically resistant, or electromagnetically transparent components for demanding environments.

Applications Across Aerospace, Defense, Automotive, and Industrial Markets

Jeco’s custom thermoforming solutions support a wide range of industries and mission-critical uses, including:

- Aerospace structural components and high-temperature carbon-fiber assemblies

- Defense and military-grade laminates, including UL94 V0 fire-rated parts

- Automotive under-hood components and lightweighting solutions

- Radomes with electromagnetic transparency

- Cryogenic door liners (including NASA applications)

- Thermoplastic armor backup structures

- Multi-cavity matched-tool parts

- Optical windows, motorcycle windshields, and clear molded panels

From lightweight composites to high-temperature laminates, Jeco’s solutions meet the highest industry demands.

Integrated Engineering, Simulation, and Rapid Prototyping

Every project begins with detailed digital design and simulation using:

- SolidWorks

- ABAQUS

- LS-DYNA

These tools allow Jeco to model part performance before production begins, reducing development time and ensuring accuracy. In-house 3D printing enables rapid prototypes, fit checks, and early-stage validation.

To maintain precision, trimming is completed on full 5-axis CNC equipment, with quality inspection supported by CMM measurement systems.

Quality, Certifications, and Manufacturing Standards

Jeco manufactures under strict quality systems to meet the needs of aerospace, defense, and industrial clients. Certifications include:

- ISO 9001:2015

- AS9100D

- ITAR Registration

These standards ensure every part meets the rigorous requirements expected in high-risk or highly regulated industries.

With 50 years of experience and a deep understanding of complex materials, Jeco remains a trusted partner for manufacturers seeking lightweight, durable, high-performance thermoformed components.