Thermoforming

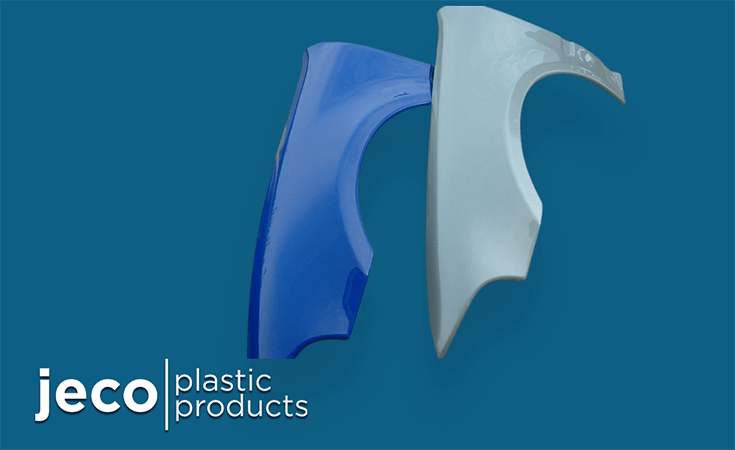

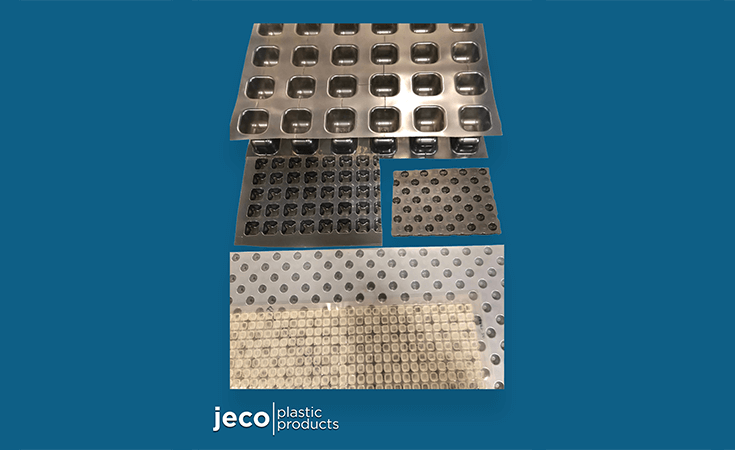

Thermoforming involves heating a plastic sheet and then molding it to a specific shape. The process finds use across a wide range of applications—from inexpensive packaging materials to automobile exterior parts.

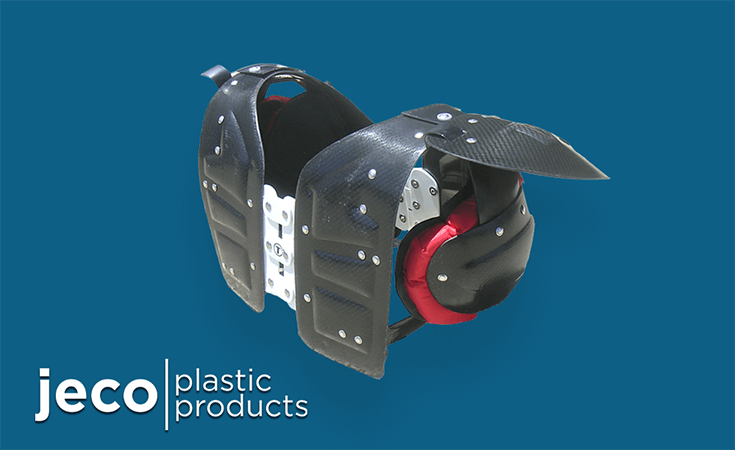

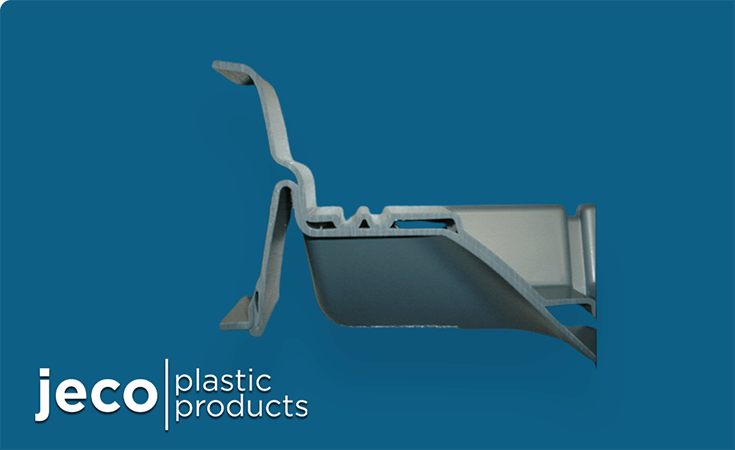

At Jeco, we take the basic thermoforming process to the next level, thermoforming a wide variety of thermoplastics and combining them with materials which have complementary physical and mechanical characteristics into specialized components for unusual applications. Jeco engineers excel in solving unique problems requiring extreme material strength, dramatic weight reduction, hard-to-form shapes, demanding environments, and severe cost constraints. Jeco thermoforming experts often can replace metal parts with strong composites to reduce weight and cost. Strict tolerances can be achieved without machining.

Jeco processes thermoplastic composites by combining pressure forming, specialized movable fixtures and often matched tools to achieve results comparable to injection molding. The Jeco method involves closely matching emission spectra from a halogen light system to the absorption spectra of engineering resins, resulting in uniform heating of thick or thin sheet stocks, or loose laminates, without degrading the surface.

The proprietary Jeco thermoforming technique permits us to:

- Use more economical tooling Make quicker tool changes

- Reduce scrap rates

- Achieve Class A surfaces in our clean room environment

- Simultaneously laminate and form dissimilar materials

- Incorporate structural elements in laminates, including topologically interlocking